Plastic shell

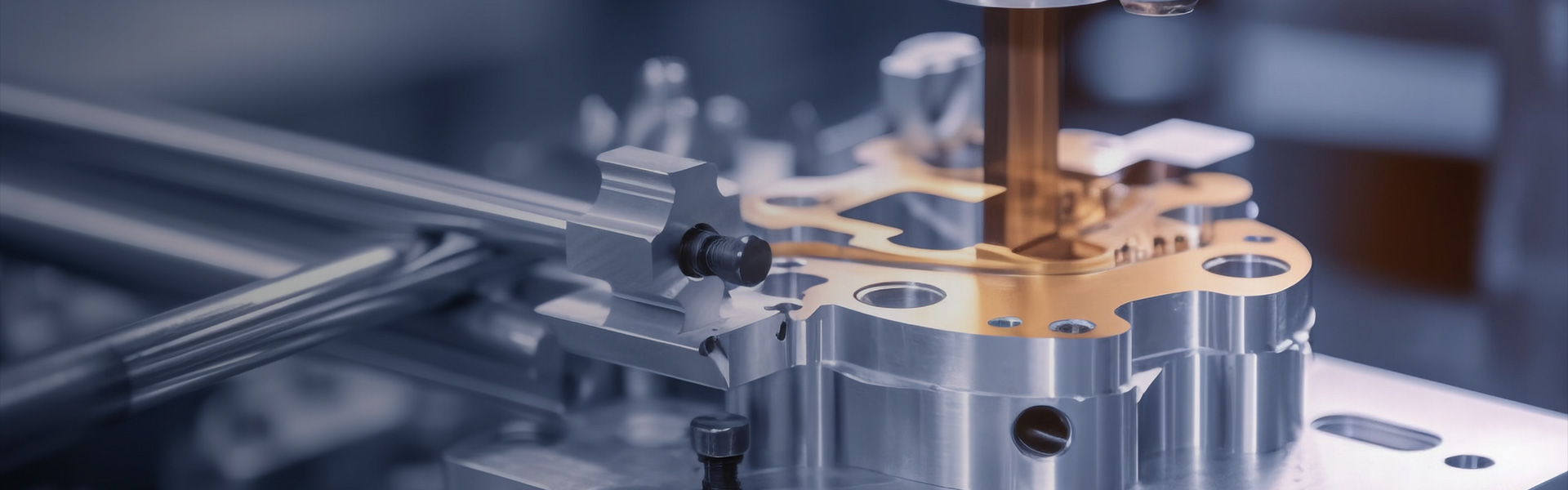

Our main service Items Are As Follows:

金属模具和工具制造

塑料注射成型

逆向工程

技术支持

数控加工、数控铣削、数控车削

冲压和冲孔

表面处理(铬锌镍锡银金镀层、粉末涂层、缎面处理等)

组装

Product Parameters

| 产品名称 | 中国优质低压压铸件 |

| 产品大小 | 定制 |

| 材料 | 铝合金等 |

| 包装方法 | OPP袋或根据客户要求 |

| 认证 | ISO9001:2015 |

| 采样时间 | 7-15天 |

| 支付方式 | TT等 |

| 交货时间 | 15天 |

Our Services

定制CNC加工服务

在ZRX,我们可以为您提供3轴、4轴和5轴数控加工、激光切割等。凭借先进的数控设备和近二十年的数控经验,我们的团队可以保证为您生产高质量的加工零件,并帮助您实现从设计、快速原型、复杂的数控加工项目到各种零部件的小批量和大批量生产。

什么是精密数控加工?

CNC(计算机数控)加工是一种使用CNC高精度机床用各种切削刀具去除原材料的制造过程,由计算机程序根据所需的几何规格自动控制。

我们的工程师和机械师将定制计算机程序,以优化加工时间、表面光洁度和最终公差,以满足您的设计规格。我们可以通过CNC加工从原型、小批量和大批量制造不同的零件。

FAQ

Q

你们是公司贸易还是制造商贸易?

A

我们是15年的专业制造商。

Q

你们以前出口过这些货物吗?出口到哪些地区?

A

我们是15年的专业制造商。

Q

你有多少员工?

A

我们是15年的专业制造商。

Q

如果我同意这个设计,你能提供我们需要的样品吗?

A

我们是15年的专业制造商。

Q

您使用的是什么包装,可以保证安全?

A

我们是15年的专业制造商。

Q

如果我们对产品有任何疑问,您能提供技术和解决方案吗?

A

我们是15年的专业制造商。

MESSAGE

186 7678 8491

186 7678 8491 rongxin896@szzrx.com

rongxin896@szzrx.com

![$info.album_alt_format[$k]](/upload/images/product/20241030/17302526926745548.jpg)